Products

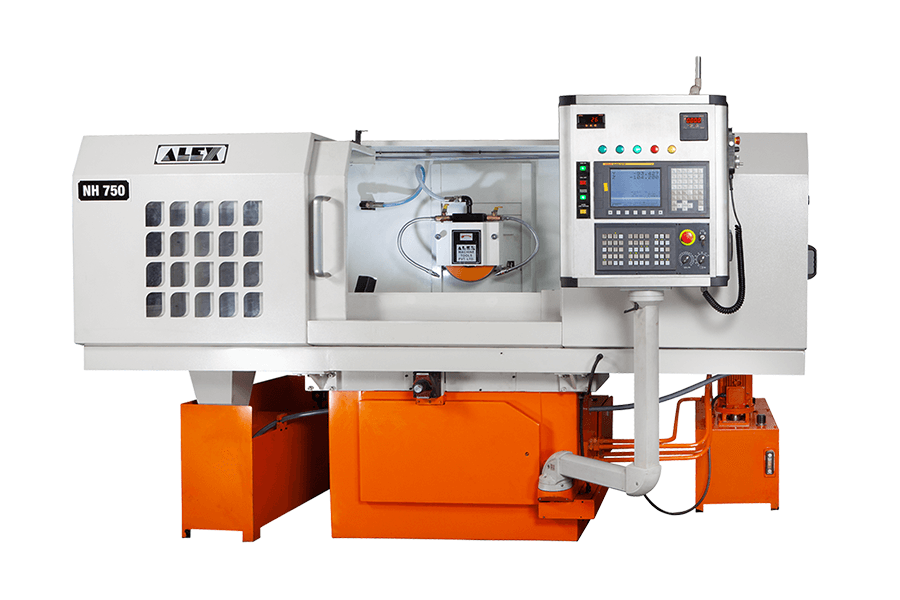

Reciprocating Surface Grinder with Horizontal Spindle

In our interaction family, we have separated all movements in the X, Y, and Z directions. We aim to achieve an accuracy of 90°± 0° in all 3 axes and maintain this accuracy throughout the machine’s life. It provides high stability even at the extreme ends of the operating range.

Our spindle runs in super-precision angular contact preloaded bearings with excellent centering and balance characteristics. This robust design is the key to the precision, accuracy, and reliability of the Alex Surface Grinder.

The spindle head travels in a vertical column in hand-scraped guideways with power elevation and manual in-feed.

Automatic in-feed can also be provided as an option.

The transverse carriage carrying the column rigidly rotates on the base of manually scraped guides using an electromechanical drive. It provides intermittent cross-feed. The line crosses the cross. This ensures that the rear support guides always support the transverse guide system uniformly regardless of the position of the column. The spindle head moves only vertically, so the grinding wheel is always at the same distance from the vertical guide regardless of the height of the work, which ensures perfect parallelism between the grinding wheel and the worktable.

The table rotates only in the longitudinal direction so that the entire grinding area is always fully supported by the guide of the front base, even when the table is in its end position.

| Models | NH-500 | NH-600 | NH-750 | NH-8040 | NH-1000 | ||

| Machining Range | Length x width (max.) | mm (in) | 500*250(20*10) | 600*300 (24*12) | 750*300 (30*12) | 800*400 (32*16) | 1000*250 (40*10) |

| Distance between table and spindle center (max) | mm (in) | 400 (16) | 400 (16) | 400 (16) | 400 (16) | 400 (16) | |

| Working Surface | mm (in) | 500*250 (20*10) | 600*300 (24*12) | 750*300 (30*12) | 800*400 (32*16) | 1000*250 (40*10) | |

| Table Load (max.) | kg (lb) | 200 (440) | 250 (500) | 400 (880) | 600 (1320) | 500 (1100) | |

| Table | Table Travel (max) | mm (in) | 550 (22) | 650 (26) | 800 (32) | 850 (34) | 1050 (42) |

| Cross Travel(max) | mm (in) | 280 (11) | 330 (13) | 330 (13) | 430 (17) | 285 (11) | |

| T – slots (number x width) | mm (in) | 1*14 (1*0.55) | 1*14 (1*0.55) | 1*14 (1*0.55) | 1*14 (1*0.55) | 1*14 (1*0.55) | |

| Table Movement | Table Speed (max) | m / minft / mm | 20 (65) | 20 (65) | 20 (65) | 20 (65) | 20 (65) |

| Cross Movement | Auto feed | mm / Stroke (Inch / Stroke) | 0.25-6(0.01 – 0.24) | 0.25-6(0.01 – 0.24) | 0.25-6(0.01 – 0.24) | 0.25-6(0.01 – 0.24) | 0.25-6(0.01 – 0.24) |

| Manual feed | mm / min (Inch / min) | 1 (0.04) | 1 (0.04) | 1 (0.04) | 1 (0.04) | 1 (0.04) | |

| Least count of hand wheel | mm (in) | 0.01 (0.0004) | 0.01 (0.0004) | 0.01 (0.0004) | 0.01 (0.0004) | 0.01 (0.0004) | |

| Vertical Movement | Manual feed rate I turn | mm (in) | 0.2 (0.008) | 0.2 (0.008) | 0.2 (0.008) | 0.2 (0.008) | 0.2 (0.008) |

| Least count of hand wheel | mm (in) | 0.002 (0.0001) | 0.002 (0.0001) | 0.002 (0.0001) | 0.002 (0.0001) | 0.002 (0.0001) | |

| Power elevation | mm (in) | 100 (4) | 100 (4) | 100 (4) | 100 (4) | 100 (4) | |

| Grinding Wheel | OD x ID x T | mm (in) | 200*50.8*20 (8*2*0.75) | 250*76.2*25 (10*3*1) | 250*76.2*25 (10*3*1) | 250*76.2*25 (10*3*1) | 250*76.2*25 (10*3*1) |

| Speed | rpm | 2880 | 2880 | 1440 | 1440 | 1440 | |

| Motors | Spindle Motor | hp (kw) | 2 (1.5) | 2 (1.5) | 5 (3.75) | 5 (3.75) | 5 (3.75) |

| Vertical up down Motor | hp (kw) | 0.25 (0.18) | 0.25 (0.18) | 0.25 (0.18) | 0.25 (0.18) | 0.25 (0.18) | |

| Cross feed Motor | hp (kw) | 0.25 (0.18) | 0.25 (0.18) | 0.25 (0.18) | 0.25 (0.18) | 0.25 (0.18) | |

| Coolant pump | hp (kw) | 0.12 (0.1) | 0.12 (0.1) | 0.12 (0.1) | 0.12 (0.1) | 0.12 (0.1) | |

| Hydraulic System | Working Pressure | Kg/cm2 (Lb/Inch 2) | 10 (140) | 10 (140) | 10 (140) | 10 (140) | 10 (140) |

| Hydraulic Pump Motor | hp (kw) | 1 (0.75) | 1 (0.75) | 2 (1.5) | 2 (1.5) | 3 (2.25) | |

| Tank Capacity | Liter | 35 | 35 | 50 | 50 | 50 | |

| Machine Size | L X W X H | mm (in) | 1250*1450*1650(50*57*65) | 1350*1640*1650(57*81*65) | 1450*2050*1650(57*81*65) | 1600*2150*1700(63*85*67) | 1890*2250*1890(75*89*75) |

| Weight | Net Weight | kg (lb) | 1200 (2640) | 1500 (3300) | 2800 (6160) | 3000 (6600) | 4000 (8800) |

| Gross Weight | kg (lb) | 1600 (3520) | 1900 (4180) | 3600 (7920) | 3800 (8360) | 4800 (10560) |

| Models | BW-800 | BW-1000 | BW-1200 | ||

| Machining Range | Length x width (max.) | mm (in) | 800*500 (32*20) | 1000*500 (40*20) | 1200*600 (48*24) |

| Distance between table and spindle center (max) | mm (in) | 450 (18) | 450 (18) | 450 (18) | |

| Working Surface | mm (in) | 800*500 (32*20) | 1000*500 (40*20) | 1200*600 (48*24) | |

| Table Load (max.) | kg (lb) | 800 (1760) | 1000 (2200) | 1200 (2640) | |

| Table | Table Travel (max) | mm (in) | 850 (34) | 1050 (42) | 1250 (50) |

| Cross Travel(max) | mm (in) | 550 (21.65) | 550 (21.65) | 665 (26) | |

| T – slots (number x width) | mm (in) | 1*14 (1*0.55) | 1*14 (1*0.55) | 3*14 (3*0.55) | |

| Table Movement | Table Speed (max) | m/minft/mm | 20 (65) | 20 (65) | 20 (65) |

| Cross Movement | Auto feed | MM / Stroke (Inch / Stroke) | 1-10 (0.04-0.40) | 1-10 (0.04-0.40) | 1-10 (0.04-0.40) |

| Manual feed | mm / min(in / min) | 1 (0.04) | 1 (0.04) | 1 (0.04) | |

| Least count of hand wheel | mm (in) | 0.01 (0.0004) | 0.01 (0.0004) | 0.01 (0.0004) | |

| Vertical Movement | Manual feed rate I turn | mm (in) | 0.2 (0.008) | 0.2 (0.008) | 0.2 (0.008) |

| Least count of hand wheel | mm (in) | 0.002 (0.0001) | 0.002 (0.0001) | 0.002 (0.0001) | |

| Power elevation | mm (in) | 100 (4) | 100 (4) | 100 (4) | |

| Grinding Wheel | OD x ID x T | mm (in) | 350*50*127 (14*2*5) | 350*50*127 (14*2*5) | 350*50*127 (14*2*5) |

| Speed | rpm | 1440 | 1440 | 1440 | |

| Motors | Spindle Motor | hp (kw) | 10 (1.5) | 10 (1.5) | 10 (1.5) |

| Vertical up down Motor | hp (kw) | 0.75 (0.56) | 0.75 (0.56) | 0.75 (0.56) | |

| Cross feed Motor | hp (kw) | 0.75 (0.56) | 0.25 (0.18) | 0.25 (0.18) | |

| Coolant pump | hp (kw) | 0.12 (0.1) | 0.12 (0.1) | 0.12 (0.1) | |

| Hydraulic System | Working Pressure | kg/cm2 (Lb/inch 2) | 10 (140) | 10 (140) | 10 (140) |

| Hydraulic Pump Motor | hp (kw) | 3 (2.25) | 3 (2.25) | 3 (2.25) | |

| Tank Capacity | Liter | 200 | 200 | 250 | |

| Machine Size | L * W * H | mm (in) | 1890*2250*1890 (75*89*75) | 1890*2260*1890 (75*89*75) | 2190*2900*1890 (75*114*75) |

| Weight | Net Weight | kg (lb) | 4000 (8800) | 4700 (10340) | 5000 (11000) |

| Gross Weight | kg (lb) | 4800 (10560) | 5500 (12100) | 6500 (14300) |