Products

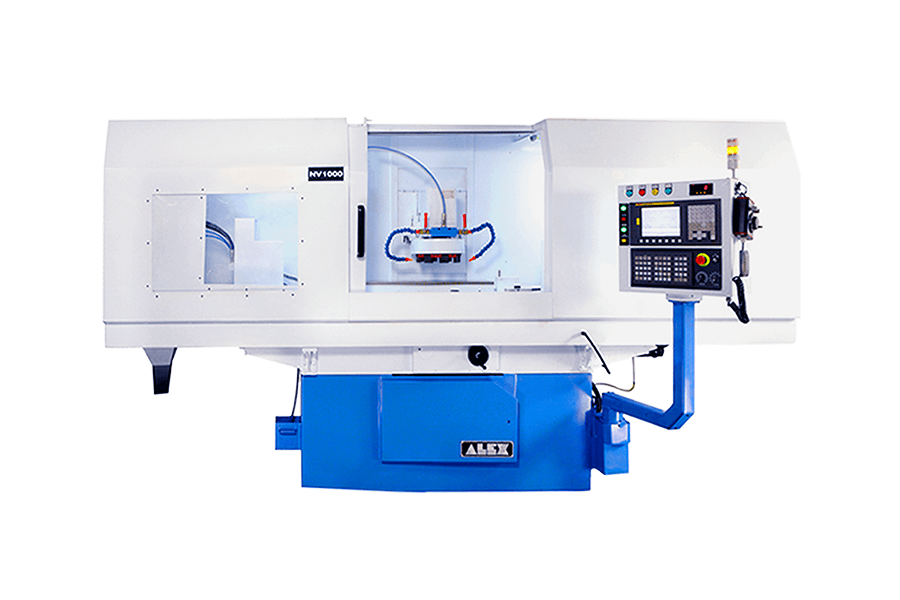

Reciprocating Surface Grinder with Vertical Spindle

This series is designed for flat grinding of one side of the job at a time for each table load. Rotary work table operates on large, circular ways-well lubricated by means of an oil sump. It carries an electromagnetic chuck with circular poles.

Access to the work table is unique, in that a greater proportion of the work table is opened for easier and safer work handling. Being a fixed center table, the initial accuracies are maintained for the entire life of the machine.

Wheel Spindle Head is of extremely rigid construction, with precision bearings duly preloaded. Segmented the wheel is directly mounted at the lower end.

The column has oversize vertical vee and flatways fully protected from grinding dust and coolant by sliding steel guards. Wheel feed can be applied by hand or power. Precision Screw gives positive down feed on the head for accurately controlling small increments of feed.

CONTROLS as Optional:

Automatic electronic gauging can be provided. It gives a continuous measurement of work during the grinding cycle and visual indications that the work is approaching size. When work reaches a preset dimension grinding stops, the machine sparks out and the Head retracts. Since the job is directly probed, wheel wear is directly compensated.

CNC controls for Vertical axis with servo drives via precision ball screw are also available as optional equipment.

OPTIONS are available to suit your specific application. CNC CONTROLS AND PLC CONTROL OPTIONS for semi or fully automatic grinding cycles.

| NV-500 | NV-750 | NV-1000 | ||

| Max. Longitudinal Table Travel | mm (in) | 550 (22) | 800 (32) | 1050 (42) |

| Max. Wheel Clearance above Table | mm (in) | 200 (8) | 250 (10) | 250 (10) |

| Working Surface over Magnet | mm (in) | 500*200 (20*8) | 750*250 (30*10) | 1000*250 (40*12) |

| Max. Table Travel | mm/min(ft/min) | 15 (50) | 15 (50) | 15 (50) |

| Power Elevation | mm/min (Inch/min) | 100 (4) | 100 (4) | 100 (4) |

| Least Count of Vertical Feed Hand Wheel | mm (in) | 0.002 (0.0001) | 0.002 (0.0001) | 0.002 (0.0001) |

| Size of Cup Wheel | mm (in) | 200*63*76.2 (8*2.5*3) | 250*63*76.2 (10*2.5*3) | 250*63*76.2 (10*2.5*3) |

| Power of Spindle Motor | hp (kw) | 2 (1.5) | 5 (3.7) | 5 (3.7) |

| Power of Elevation Motor | hp (kw) | 0.25 (0.18) | 0.25 (0.18) | 0.25 (0.18) |

| Power of Coolant Motor | hp (kw) | 0.13 (0.09) | 0.13 (0.09) | 0.13 (0.09) |

| Cross Feed Motor | hp (kw) | 0.25 (0.18) | 0.25 (0.18) | 0.25 (0.18) |

| Speed of Grinding Spindle | rpm | 2880 | 1440 | 1440 |

| Working Pressure | kg / cm (lb/Inch ) | 10 (140) | 15 (210) | 15 (210) |

| Power of Hydraulic Pump Motor | hp (kw) | 1 (0.75) | 2 (1.5) | 2 (1.5) |

| Tank Capacity | liters | 35 | 50 | 50 |

| Machine Size | mm | 1250*1450*1650 | 1450*2050*1650 | 1450*2300*1650 |

| Length*Width*Hebight | (Inch) | 50 * 57 * 65 | 57 * 81 * 65 | 57 * 90 * 65 |

| Net Weight of Machine | kg (lb) | 1200 (2640) | 2800 (6160) | 3200 (7040) |

| Gross Weight of Machine | kg (lb) | 1600 (3520) | 3600 (7920) | 3800 (8360) |